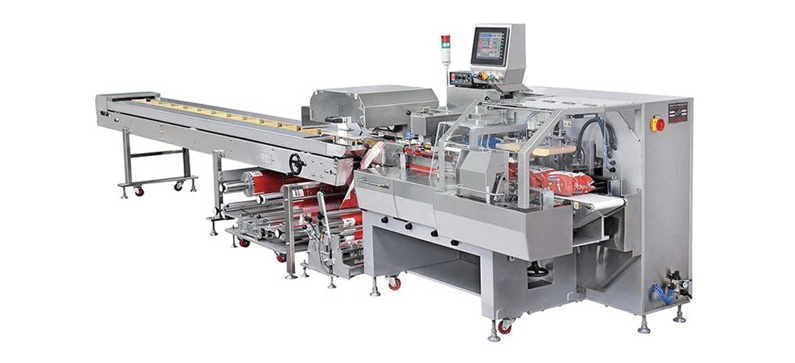

In the ever-evolving field of industrial technology, automatic packaging machines stand out for their high efficiency and high precision. They have redefined how products are presented and profoundly changed the way the industry operates.

Automatic packaging machines have become the key to efficiency and precision in modern manufacturing. They are widely used in food, beverage, pharmaceutical and other industries.

These advanced machines not only simplify the packaging process, but also make a significant contribution in terms of quality control, cost-effectiveness and environmental sustainability.

1. Simplify the Packaging Process

Why are automatic packaging machines popular in the market? Because they simplify the complex packaging process.

In traditional manual packaging, the operation is relatively cumbersome, and human factors can also lead to quality problems. And now, by using automatic packaging machines, products can be packed efficiently and accurately.

In a constantly changing market demand, it is important to remain competitive in the market. Ruipuhua’s automatic packaging machines provide manufacturers with efficient solutions.

Their automatic packaging machines make the entire packaging process more efficient through precise operation. This simplification increases productivity while ensuring packaging quality.

2. Quality Control

In addition to packaging efficiency, packaging quality is also important. So how is the automatic packaging machine of Ruipuhua to ensure the quality of packaging?

On one hand, through precise operation, their automatic packaging machines complete packaging tasks in a highly automated way. Its advanced control system ensures that every step is executed accurately, enabling fast and error-free packaging.

On the other hand, the automatic packaging machines from Ruipuhua use advanced sensing technology to monitor parameters during the packaging process in real time. These parameters include product position, condition, and potential quality issues. This can quickly capture abnormal conditions, then the automatic packaging function is adjusted in time to ensure product quality.

3. Cost Effectiveness

Automatic packaging machines by reducing labor costs and improving production efficiency to achieve significant cost benefits.

Compared with manual packaging, automatic packaging machines can reduce labor costs. They can complete a large number of packaging tasks in short time without additional human input.

In addition, the fast and precise packaging process of automatic packaging machines allows manufacturers to complete a large number of packaging tasks faster, so that they can adapt to changes in the market more quickly.

Although the cost budget of the automatic packaging machine will be a little larger, the long-term benefits are significant. Manufacturers can benefit from higher production capacity and lower operating costs over time by reducing labor costs and increasing productivity.

4. Environmental Sustainability

Automatic packaging machines can reduce packaging waste. How to do that? In its efficient packaging process, packaging materials can be used more efficiently.

In contrast, traditional manual packaging may cause waste due to human operation, and automatic packaging machines do not have this problem. Because the machine is precisely measured and operated, the use of unnecessary packaging materials can be reduced.

Moreover, modern automatic packaging machines are also paying more and more attention to energy saving in design. For example, Ruipuhua’s automatic packaging machines use advanced technology. This can reduce energy consumption during operation. In addition, their automatic packaging machines use biodegradable materials. This helps to reduce the adverse impact on the environment.

Conclusion

Automated packaging machines have profoundly changed the way the industry operates by simplifying the packaging process, improving quality control, achieving cost efficiency and driving environmental sustainability.

In the future, automatic packaging machines will continue to play a vital role in the manufacturing industry. As technology continues to advance, Ruipuhua will continue to innovate to enable machines to better meet changing and growing industry needs.